Equipment

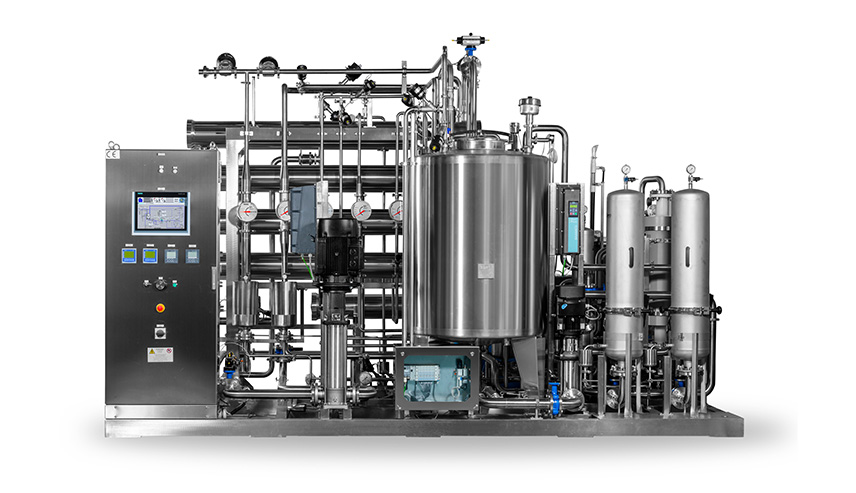

PRO-X⁹⁰

The PRO-X90 is a novel pretreatment system based on Reverse Osmosis membranes with full integrated IIoT (Industrial Internet Of Things).The goal of this technology is to guarantee high recovery rates (at least 90%) managing raw feed water, ensuring significant up-front and operating cost savings for the end user.

PRO-X90 is Stilmas' most innovative equipment for pretreatment, able to minimize feed water consumption and treat water with high level of silica and hardness; the system, based on RO membranes, operates in semi-batch way. Thanks to the characteristics of the membranes, compared to a traditional system, PRO-X90 is able guarantee an extremely robust bioburden barrier, preserving and extending the lifetime of the subsequent pharmaceutical water process stages.

The PRO-X90 can generate from 3 to 50 m3/h of pretreated water. The self-modulating function allows the user to satisfy a wide range of different consumption patterns.

Application fields

Application fields

- Pharmaceutical

- Biotech

- Veterinary

Technical Description

PRO-X90 works in semi-batch mode: production and discharge phases alternate, thanks to an adaptative algorithm that manages the phases alternation interpolating various variables on the membrane system.

Sustainability at glance

- High recovery rate (higher than 90%)

- No chloride in the sewers

- High protection against bioburden on pharma stages (WFI generation)

- Self recovery adjustment through an adaptative algorithm

- Variable production in place

Reduced Operating Costs

- Reduced OPEX on whole pharma water treatment system (at least 50%)

- Self-modulating system adapts to process feed quality and demand to minimize water consumption

- Each system size features a product flow range: system flows are customized to the end user’s requirements by dialing in the required product flow rate to ensure water and energy consumptions are optimized

Advantages on the following pharma water stages

- Less sanitization cycles

- Enlarged lifetime of membranes and media

- Reduction of OOS (Out Of Specification)

- Less lab investigation

- Drastic reduction of downtime and relevant quarantine period